Best Practices for Surge Protective Device (SPD) Management

Checking surge protective devices

Having your electrical equipment damaged during a storm can prove very costly; to make matters worse, it can be quite difficult to get compensation from your insurer. Learn what measures you can take to boost your chances of a successful claim and avoid any trouble with your insurance policy.

Electrical equipment damage caused by storms can be financially costly, especially when insurance claims are denied due to discrepancies in documentation or non-compliance with design specifications. In order to help with this electrical engineers and property owners should start by focusing on the proper installation, maintenance, and documentation of surge protective devices (SPDs).

Electrical damage during a storm

Storm-related electrical damage can severely impact multiple appliances such as televisions, refrigerators, gaming consoles, audio equipment, central heating and heat pumps. Damage to these types of appliances often occur due to lightning strikes that cause voltage surges or transients. While having an insurance policy in place can seem like a safeguard against costly replacement of equipment, it is crucial to ensure proper documentation and adherence to electrical standards is made to prove suitable precautions have been made.

Investigating damage caused by surges

When investigating damage caused by surges, an expert is likely to review the design, installation method and inspection certificates for the electrical system. This type of investigation will check for any inconsistencies between the installed SPDs and the design specifications along with inspection certificates. This highlights the importance of aligning actual installations with approved plans and obtaining proper documentation from certified electricians.

Checking surge protective devices with insulation resistance meter

Best practices for managing SPDs

Regular Inspections

Thorough inspections should be conducted at least every five years or immediately after any suspected lightning strikes. These inspections should be documented by a certified electrician to ensure compliance with electrical standards and regulations.

Using Reputable Manufacturers SPDs

Surge protective devices from well-known manufacturers should be used. These manufacturers will be able to provide certifications from accredited laboratories which can serve as robust evidence in legal disputes, proving the quality and reliability of the installed SPDs.

Regular Testing of SPDs

Use specialised SPD test equipment provided by manufacturers or utilise advanced insulation resistance meters capable of assessing the SPD functionality. Proper testing ensures that SPDs are operating within specified parameters (e.g., maximum continuous operating voltage) and can effectively mitigate surge damage.

Testing Techniques

One practical method involves using an insulation resistance meter, such as the Sonel MIC-2511, with a ramp function to quickly identify varistor degradation or leakage currents indicative of failing components.

Check the functionality of your surge protective devices

Standards that cover surge protection devices include IEC 60364-4-44:2024 Low-voltage electrical installations – Part 4-44: Protection for safety – Protection against voltage disturbances and electromagnetic disturbances. In addition to this, the standard IEC 62305-3:2024 Protection against lightning – Part 3: Physical damage to structures and life hazard, has section D.6.7 which states that “Surge protective devices (SPDs) (and their protective measures, if applicable) shall be inspected in accordance with the manufacturer’s instructions at intervals not exceeding 12 months or whenever electrical tests of the LPS are performed. SPDs should also be inspected whenever an object is suspected to have been struck by lightning.”

It should be considered that an LPS (Lightning Protection System) refers to a lightning protection system installed both externally and internally, including SPDs in the main distribution board of the building. An inspection certificate for the LPS, including surge protective devices (SPDs), will serve as a compelling piece of evidence should an incident occur as it will demonstrate your utmost diligence in preventing sudden and transient voltage surges in the electrical network.

It should also be noted that section E.7.2.4 of the referenced standard states that “SPDs without visual indicators require testing, preferably using guidelines or devices provided by the manufacturer.”. The problem is that a visual indicator alone does not guarantee that an SPD, especially one of questionable quality is functioning properly and remains operational. In addition, not all manufacturers provide devices for testing their products; those who do so often take precautions to prevent these devices from being used to test competitors’ products (e.g., by incorporating RFID codes inside their SPDs). Moreover, the prices of these devices, mostly single-function ones, are exceptionally high.

Using an insulation resistance meter with an SPD testing feature

One solution is to use an insulation resistance meter with a voltage ramp function and rapid voltage cut-off when a leakage current of 1 mA is detected. This value is directly derived from “IEC 61643-11:2011: Low-voltage surge protective devices – Part 11: Surge protective devices connected to low-voltage power systems – Requirements and test met”.

Surge protective devices (SPDs) are often constructed using varistors, which degrade over time. This degradation is primarily due to leakage current, i.e. a small current passing through the varistor from the phase conductor to ground. Initially, this current is approximately 1mA, but it increases over time, causing the varistor to overheat and can eventually lead to a short-circuit. In some surge protective devices (SPDs), a similar but lesser effect is created by operating current, which flows between phases or by direct current, conventionally from the “+” terminal to the “−” terminal.

This degradation is influenced also by factors such as the following:

- Elevated temperature (e.g. in PV systems)

- Humidity

- The number of properly diverted surges.

Furthermore, direct current accelerates the ageing of the varistor’s structure more than alternating current.

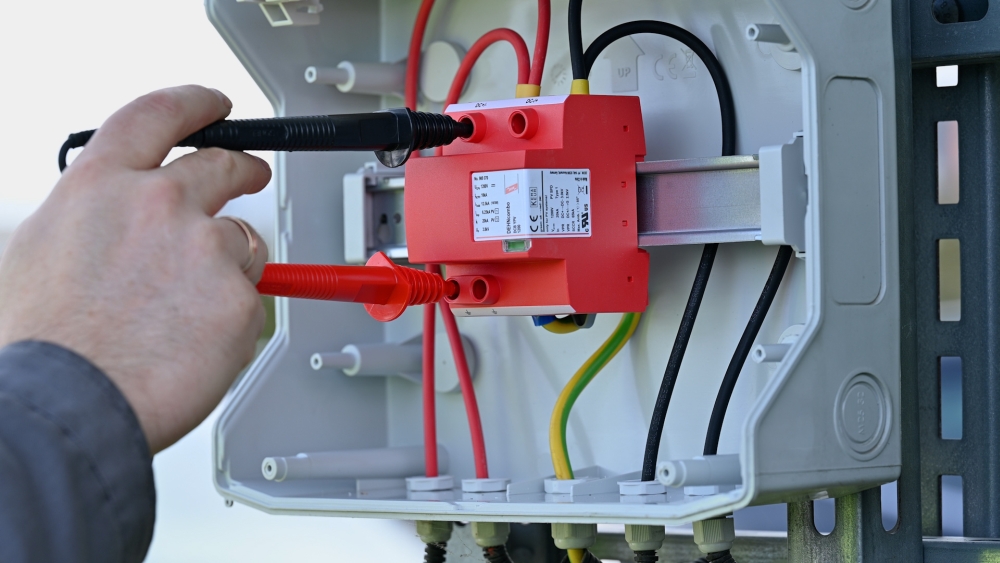

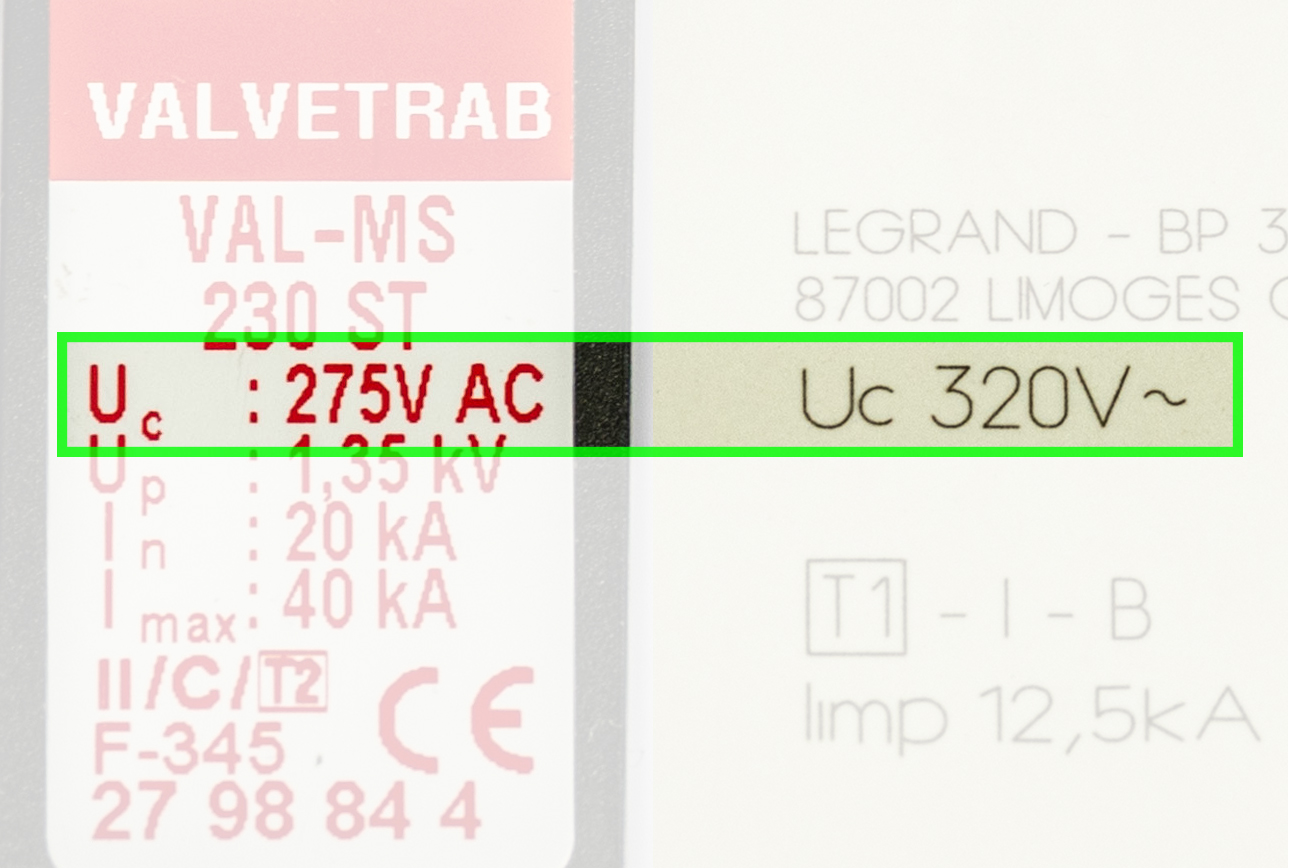

Typical residential Uc voltages

In residential installations, this is typically Uc = 260…335 V AC, while in photovoltaic installations, the maximum continuous operating voltage (UCPV) can exceed 1500 V DC. In ICT installations, which also require surge protective devices, voltages usually range from several to several dozen volts.

Solar PV maximum continuous operating voltage (UCPV) can exceed 1500 V DC

Sonel offers a device that verifies the maximum continuous operating voltage (Uc) declared by the SPD manufacturer. The Sonel MIC-2511 insulation resistance meter has recently been upgraded with a new feature to enable the testing of SPDs. The meter converts the measurement voltage from DC to AC and classifies the SPD type as either varistor-based or spark-gap-based. The measurement process is straightforward and takes an experienced technician no more than a minute per SPD. Just disconnect the surge protective device from its base or, preferably, turn off the power during the measurement. Then, select the SPD feature and choose the maximum continuous operating voltage. This selection is necessary only for compliance assessment (pass/fail).

Checking surge protective devices with Sonel-MIC-2511

Summary

Given the variability in storm frequency across different regions, from approximately 20-40 days annually in Central Europe to up to 200 days in other areas of the world, it is essential to implement robust preventive measures against electrical surges. By referring to best practices for SPD management, through regular inspections, use of reputable products, rigorous testing, and meticulous documentation, you can significantly enhance the quality of the protection at the property and understand any unique vulnerabilities it may have. By taking proactive steps towards mitigating risks not only protects your assets but also ensures that you are fully prepared when facing unforeseen electrical emergencies caused by the unpredictable nature of severe weather events.

Learn more about our products and services by visiting our Power Quality Expert product catalogue, Sonel product catalogue , Electrex product catalogue or Elspec product catalogue or you can contact us to discuss your measurement requirements further.

You can also follow Power Quality Expert on LinkedIn for regular news on products, events and technical updates.